Established in 1983, Phoenix Inspection Systems are specialists in design and manufacture of ultrasonic non-destructive testing (NDT) solutions serving a wide range of industry sectors including nuclear and power generation, offshore oil, gas and petrochemical, aerospace, composites and rail. The products take into account the full range of ultrasonic NDT techniques, including phased array, corrosion mapping, pulse echo and TOFD and are built to the internationally recognised Quality Management Systems standard ISO 9001:2008.

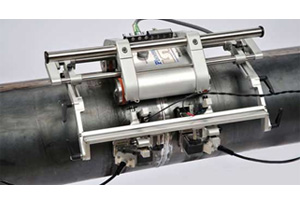

The MagScan: a magnetic dual axis motorised scanner, is the ideal tool for corrosion mapping. The dual axis function allows for inspections such as raster scanning and for testing pipe to elbow welds, and any flat or curved surfaces.

The MagScan can be used on everything from flat plate to pipes as small as 4” O/D. Its compact size means it can be set up by one operator and is suitable for phased array, TOFD, and corrosion mapping. The MagScan can be connected to the Phoenix MCPA motor controller.

Download BrochureKey Features

- Strong magnetic wheels allow for use on painted surfaces

- High speed inspection (up to 40mm/sec)

- Inspects pipe diameters from 4”O/D up to flat

- Scanning arm adjustable up to 250mm

- Compact (227mm x 198mm x 126mm) and lightweight (5kg)

- Quick release probe adjustment

- Manual toggle switch enables quick setups

- Servo constant speed control

- Phased Array, Corrosion Mapping and TOFD assessment

- Two axes for raster scan inspection

- Simultaneous phased array and TOFD inspection

- Operates in any orientation

- Holds up to 6 probes

- Probes independently sprung and gimballed

- Probes can be positioned to any PCS

- Integrated couplant and probe manifold

- For use with any instrumentation or motor controller

- Laser or chain guide option

- IP66 rated

- ASME code compliant